Naughtright Fire Company, Part 1 of 2: Construction

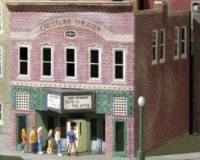

To be honest, I never liked the look of the Miller Engineering Fire Engine Co. #2 kit, even though it's quite "classic," and I've found several photos of real buildings just like it. But the more I looked at the Crestline Theater, the more I saw it as my firehouse. So, in a strange twist of irony, I wound up using much of the firehouse kit for the theater, and much of the theater kit for the firehouse!

Thus begins a long and winding tale of a project that took a long and winding path to completion. The first problem was that Miller Engineering switched this kit from brass to stainless steel (which makes no sense to me because the structure is 98% brick), and stainless steel is a much harder material to use for kitbashing. I needed an older version of the kit, when it was still brass, and thanks to eBay I was able to get one. (Actually, I needed a couple, as I botched the first one.)

My plan was to emulate what I'd done in N scale for my White River and Northern III. Real-life inspiration for that project came from a firehouse in Ewing, New Jersey, which has since been replaced. My Laube Volunteer Fire Company building was based on a modified Design Preservations Models kit: I replaced the storefront with a pair of scratchbuilt (and functional) roll-up doors.

After a quick stroll through a couple hundred reference photos, I learned that there were no hard and fast design rules to follow; like the theater, I could do just about anything within reason. So, I started by making one large door on the left and leaving the small door intact on the right. The large opening was finished off using a piece of fret from an N scale high-tension tower kit, plus a thin strip of plain brass. It was a lot of work, but after hours of cutting and soldering, it just didn't look anything like what I had in my mind's eye. I tried to live with it for a while, but ultimately I hacked it all out.

The gaping hole was both a liberating sight and a reminder of the time, energy and materials wasted on a futile effort. I realize this comes with the territory of kitbashing, but it's still irksome. Even more frustrating, my lengthy search for something else to fill the hole did not produce any workable solutions, despite having an obscene supply of etched brass materials on hand.

Eventually I started making progress by thinking outside of the Z scale box. In the past I've had good luck mixing parts from different scales (for instance, I discovered that N scale bricks make good Z scale shingles), and this time the solution came in the form of the Miller Engineering N scale Gulf Gas Station kit. It was quite remarkable: I could not have designed better doors myself. Particularly intriguing was that, once installed on the firehouse, the porcelain panels of the garage magically became cut stone blocks—perfect. (One may question the sensibility of purchasing an entire kit for just one part; this is valid, and I often wrestle with the issue myself. At the moment, I don't have a good answer.)

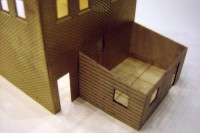

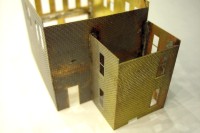

Meanwhile, I was also working on the other end of the building, where I was planning an extension. At first, it was going to be a simple wooden structure tacked on the back, which I'd cobbled together from some laser-cut leftovers (of which I have entirely too many). It was nearly finished, but when I placed it up against the back of the main building, my face scrunched up into an "I'm not lovin' it" frown. For one thing, it would be impossible to see from the front of the layout, and while that's not all-important, I did want to more effectively break the pattern of yet another rectangular building for the town.

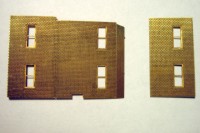

What I needed was a two-story extension, preferably one that blended in cosmetically with the main building. As it happened, one of Miller Engineering's two townhouse kits—which sat in a drawer, unlikely to ever be used—had, by happy coincidence, brickwork and windows identical in size and style to the main building. And so before you could say "kitbash," I had the townhouse walls chopped up and soldered onto the back of the firehouse. Could it have been better? Absolutely. Would it do? Absolutely.

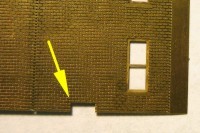

One small problem of using the townhouse kit was that, upon cutting it down, a bit of a door opening remained along the lower edge of one wall. At first I had visions of soldering a patch in the opening, and fretting over the visible seams, with plans to cover the seams with vines or something after installing it on the layout. But when I let my imagination wander a little, I realized this potential liability could instead be turned into a benefit: thus it became a basement window!

To add to the convoluted progress of the project, after I had finished ever-so-neatly soldering the chimneys to the walls, I made the surprising discovery that Miller Engineering had committed a faux pas in their design of this kit—two of them, actually: they placed windows right under the chimneys—on both sides! I was going to let it be, and treat it like a brain teaser for people ("What's wrong with this picture?"), but then decided I didn't like compromising the building's appearance that way. So, I clipped the chimneys off, and touched up the wall caps with a little solder. With that, the main building was at last finished, and I could move on to the fun stuff: detailing.

One of the more important details of the typical firehouse is the siren. After flipping through a bunch of reference photos for ideas, I started with a section of tower extracted from an old Scale Link N scale windmill kit that I'd botched. The siren itself began as a pair of N scale dust separators from a Green Max industrial detailing kit; the two vent caps were grafted together to form the classic profile of a typical siren. The siren's base was a sliver of the dust separator left intact and trimmed square; this was bonded right to the top of the tower with CA. Then I carefully sanded the legs to suit the slope of the roof. (Photos can be seen in Part 2.)

Another common firehouse rooftop detail is a set of radio antennas. Sometimes they'll be tacked onto the siren tower, but sometimes they'll have their own tower. I made my antenna tower from more of the same N scale windmill (a handy and versatile kit in multiple scales). After soldering the tower sections together, I topped it with a tiny square of strip styrene, which I drilled to accept a piece of fine steel music wire. Since such towers often sprout a small forest of antennae over time, I also added a couple of bits of stainless steel fret material (I do not throw away anything!) to the sides of the styrene cap. Not only is it a lot of fun for me to make details such as this, but they give structures an authentic and lived-in look. (Photos can be seen in Part 2.)

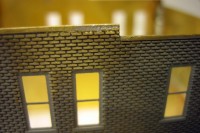

Wrapping up the exterior principally involved the roof, which I made from styrene. Like all Miller Engineering downtown structure kits, the roof is dead flat (I imagine out of necessity, given the medium), whereas real roofs on buildings such as these are more often sloped. I bonded .040-inch thick strips of styrene to the top edges of the walls with CA to complete the caps; the bottom edges of these strips were cut on an angle to form the roof slope. Then, I cut a plain rectangle of .020-inch thick sheet styrene to fit the building interior, and bonded it to the strips with liquid styrene cement. A layer of masking tape strips for texture finished the roof.

Next came the cornice. As I have for all of these kits, I replaced the original brass part (which is just a flat piece mounted on an angle—not very convincing) with one that I fabricate from styrene. After reviewing some reference photos, I decided to make a very plain cornice with two pieces of styrene angle stock nested together.

The optional brick trim piece to cover the "Crestline Theater" sign was applied backwards—with the plain side out—in preparation for the new sign. This pretty much left the building ready for finishing and detailing, which will be covered in Part 2.

My kitbashed N scale firehouse inspired the Z scale version.

Miller Engineering's Fire Engine Co. #2 never appealed to me.

The Miller Engineering Crestline Theater kit will become the firehouse.

The Miller Engineering N scale Gulf Gas Station kit will provide the doors.

This Miller Engineering brick townhouse will eventually become the extension.

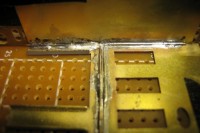

The original doors and entrance are removed from the front wall.

In spite of being a lot of work, this front wall design is deemed unsatisfactory.

The N scale gas station doors are soldered into the entrance opening.

The new doors fit perfectly and look exactly right.

This wooden addition on the back is not creating the right effect.

Townhouse walls are cut down to make a new extension.

This liability is turned into a benefit by becoming a basement window.

The extension is soldered into place on the back of the main building.

What's wrong with this picture? Notice where the chimney is located...

The chimneys are removed and the surface is cosmetically corrected.

Styrene strips are applied to the edges of the walls to establish the roof slope.

The sheet styrene roof is covered with masking tape for texture.

Copyright © 2007-2013 by David K. Smith. All Rights Reserved.

Miller Engineering product photos used with permission.