Naughtright Passenger Station, Part 3 of 5: Roof

The roof nearly became a deal-breaker. Originally I'd planned on using the roof parts left over from the Miller Engineering barn kit (which I scavenged for the eves). But then I made a startling discovery: the roof of this little station was longer than the barn roof!

In fact, I could not find parts from any brass kit—and I have nearly all of them—that were big enough. While I got away with piecing together larger parts from smaller scraps to produce the eves, I was not going to get away with the same trick for the roof, as the piecework would be all too obvious.

Then it dawned on me me: N scale brick just might be an acceptable stand-in for Z scale shingles. Not being a brick- or shingle-measuring purist, I strive for an effect, which can be accomplished without having to be dead-on accurate.

Expanding my search to include N scale kits, I discovered that the Miller Engineering theater is one of the few buildings with relatively windowless side walls, which is exactly what I needed. Saying goodbye to a future N scale project, I hacked up the side walls into the four pieces needed for the station roof, using a paper mockup to get all of the angles right.

The tiny chimney took nearly as long as any other major assembly. Eight bits of brass brick were bonded onto a length of square telescoping tube stock. Another length of the next size smaller tube stock did double-duty as the liner sticking out the top and also the anchor to the roof. I was not about to expect cyanoacrylate to reliably hold a painted brass chimney to a painted brass roof, and there was no way to solder the tiny assembly together—at least not within my capability.

Attaching the roof to the eves was probably the most nerve-wracking part of the whole project. Solder was obviously not an option, leaving cyanoacrylate as the only logical alternative. But I'd have only one shot at getting it right, with loads of opportunities to mess everything up. After rehearsing the procedure several times, I put on some nice, calming music, took a deep breath, and pretended that I knew what I was doing...

The last item on the to-do list for the station project is the platform, which will be the only non-brass part of the structure. It will be made from styrene, mostly because it's not as easy to distress brass as it is styrene in order to simulate old concrete.

By the way, for much more detailed information on construction, see the Bashing Brass Buildings clinic.

The chimney slips down over a length of square tube soldered into the roof.

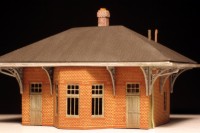

The finished station from the trackside point of view.

In addition to the chimney, roof details include a vent pipe and electric conduit.

The gutters slant downward toward the downspouts, as they would in life.

It's interesting how N scale brick can pass for Z scale shingles.

The station is positioned on the layout roughly where it will be permanently.

Copyright © 2007-2013 by David K. Smith. All Rights Reserved.