Introduced in March 2010, the 9000 Series is Eishindo's second trainset. A set comprises four cars: the two end units are powered, and contain directional lights; the two center cars are non-powered. The 9000s have Eisnindo's second-generation mechanism, which is considerably better-running and more reliable than their 103s.

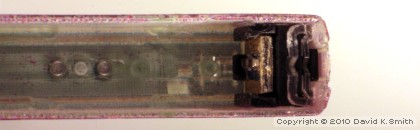

The powered chassis is a self-contained mechanism; the shell simply slips over the top. The drive train is permanently assembled and cannot be dismantled without cutting parts that cannot be repaired or replaced. The trucks are held in place with tension springs; these can be replaced if necessary. Drawings are not to scale.

Primary parts: In the foreground, from left to right, are the pilot, lighting fixture, LED unit, and pantographs (still attached to the sprues). In front of the shell is the undercarriage detailing part. Note to kitbashers: Although it may appear there is room to shorten the chassis, there really isn't. The gap between the motor and the truck tower is deceiving; the problem is that there is no room for the truck to move forward because of the motor bulge on the underside of the chassis. Plus, the mechanism is permanently assembled: the electrical strips are secured to the gearbox by melted pins. Removing these pins leaves no practical way of reattaching the electrical strips. All chassis parts are made from engineering plastic, so there's no way to glue or bond the parts. Copyright © 2008-2012 by David K. Smith. All Rights Reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||