O'Malley's Triangle Bar, Part 1 of 2: The Sign

As a project, O'Malley's Triangle Bar began as a sign in search of a building. I wanted to feature the Light Works USA animated bar sign, but the sign is considered large in N scale, so in Z it's bordering on outlandishly huge—six feet wide by eighteen feet tall in Z scale.

Still, I had a sense it might be possible, but in order to carry such a big, bulky thing believably, a three-story building as a minimum was needed, one with sufficient mass and presence to balance the billboard-sized sign. Coincidentally, Micro Structures' Triangle Hotel & Bar had what it took.

As a bonus, the bar had a perfect mounting point for the signs: the second- and third-story windows on the narrow end of the building. Now, granted, I'll admit that the location of the sign was chosen for best viewing by 1:1 people, as opposed to 1:450 folk, but in this case I didn't think it was so illogical as to be completely implausible. Indeed, once the building was finished and the sign installed for good, it looked quite natural.

Light Works signs are impressively thin; however, they're made of clear plastic, which pretty much defeats the illusion of free-standing letters that Miller Engineering was attempting to create, and the backs of the signs are unsightly. Also, mounting two signs directly back-to-back would have made it impossible to attach the electrical connectors.

To address all of these problems at once, I assembled the sign pair into a single, solid structure made to look like a boxy lighted sign, in keeping with many such signs in real life. After painting the backs of the signs with black paint, I laminated them together with a chunk of 1/16-inch thick double-sided foam tape. I also blacked out the lighted strips connected to the letters with a black Sharpie. To complete the sign, I made a trim strip from stainless steel fret material, which I bent to the shape of the sign and bonded in place with a couple of tiny drops of CA.

Cautionary note: As I learned first-hand, these signs are extremely easy to damage with sharp tools like knives, as well as with chemicals such as solvent-based paints. Every effort must be made to handle them with great care and avoid exposure to harmful objects or substances.

The sign fit into a slot created by joining the the second- and third-story window openings on the narrow end of the building. In a happy accident, the fit was such that it didn't require any cosmetic trickery; the height and width of the sign matched the opening perfectly. It was held in place with a pair of square styrene strips bonded to the sides of the sign and the interior of the wall at the opening.

The sign was installed after the bar was finished—follow along on the kit build.

This is how the Light Works USA sign appears as advertised.

Unfortunately, in real life the clear plastic base is too obvious.

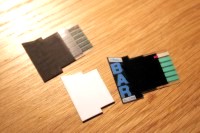

The backs of the signs are painted black and then laminated together.

The signs are tested after being assembled.

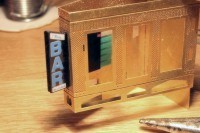

The assembled sign is test-fit in the enlarged building opening.

The stainless steel trim completes the sign and it's installed on the building.

Copyright © 2007-2013 by

David K. Smith. All Rights Reserved.

Miller Engineering product photo used with permission.