Battle of the Geeps

by David K. Smith, 27 July 2008

It's the American Z Lines GP7 versus the Micro-Trains GP9

in a Z scale model locomotive death match!

There can be only one champion!

Which one will it be?

With all of the discussion taking place on the Internet as to which is better, I decided somebody ought to break out the test meter and the calipers and make a definitive statement using the scientific method, because one cannot rely solely on brand name or anecdotal remarks. And being as I have no publisher with advertising contracts to worry about, I'm free to be brutally honest; as a consequence, some of the results may come as a surprise.

|

|

|

|

|

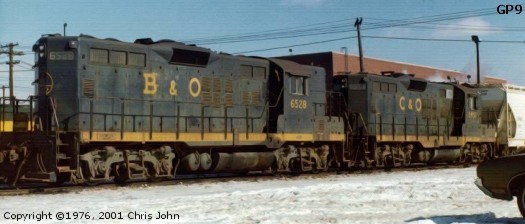

First, a little bit about the real thing. The success of the GP7 (GP for General Purpose) ironically came right on the heels of the dismal BL2, and established EMD as the preeminent diesel builder, outselling the competition by more than two to one. Over 2,700 GP7s were built between 1949 and 1958, originally purchased by over 70 railroads, so we won't run out of paint schemes anytime soon. Around 4,100 GP9s were built between 1954 and 1959, quite a few of which are still running—albeit often rebuilt and modified. While the two are very nearly identical externally, internally they're quite different, although the extra horsepower of the mechanically more robust GP9 (1,750 versus 1,500) doesn't really amount to much, and was achieved by simply raising the upper RPM limit of the prime mover.

Now to address the two quasi-competing Z scale models of these popular old locomotives. I've divided the evaluation criteria into the following categories:

- Accuracy: a comparison of the model's overall dimensions with those of the real locomotive

- Fidelity: an evaluation of the faithfulness of the detailing

- Construction: how the mechanism and shell are designed, and the salient features of each model

- Fit and Finish: the quality of the manufacturing

- Performance and Price: how the model behaves on the rails, and how much it will set you back

- Conclusion: some closing thoughts, plus the report card

The following table compares the models' principal dimensions, rounded to the nearest inch, with those of the prototype (GP7s and earlier GP9s share all of the same dimensions):

|

*These lengths are estimated from drawings. Published locomotive specifications indicate overall length from coupler to coupler, but measuring models in this manner is not very meaningful given the mechanics and limitations of model couplers—for one thing, AZL offers two coupler mounting options, truck and body, which results in a 6-inch difference in length.

|

|

|

|

|

|

|

Some claim that high dimensional accuracy is not as important in Z scale. However, in some cases we're not talking about discrepancies of a few scale inches, but of well over a foot, which for the smaller dimensions (such as hood width) noticeably impacts the model's basic appearance. In life, these high-nose Geeps are "tall, slender ladies" with a distinctive look, particularly from the ends. With its remarkable dimensional accuracy, the AZL model successfully captures this look, whereas the M-T model—its hood weighing in at nearly a foot and a half (or 25%) too wide—just looks "fat" by comparison, making it more of a caricature than a scale model. It's actually quite startling to see the two models side-by-side and to realize that they're supposed to look virtually identical.

Some also contend that the GP9's over-width hood is not noticeable in typical use. This might be true on layouts that restrict the viewing angle of the locomotive to the side only; otherwise, as soon as one views it head-on or from above, it will certainly become noticeable—at least to those modelers familiar with what a GP9 is supposed to look like. Despite this, M-T is forging ahead with plans for more new hood units of similar design, with no plans to build anything having the correct width—proof, I suppose, that they have enough satisfied customers to make it worthwhile to carry on making "fat" models. Well, all I can say is that my wallet is relieved to hear this!

As an aside, Model Railroader declared Micro-Trains' GP35—which suffers from many of the same dimensional distortions—to be an "extremely accurate model" and that the "dimensions are right on" ("Z scale GP35 measures up in every way," September 2006, p. 84). Given some discrepancies of nearly two scale feet, how they arrived at this dubious conclusion surely must have been influenced by the dimensions of the advertising contract between Kalmbach and Micro-Trains—which should by no means be construed as a slight against M-T.

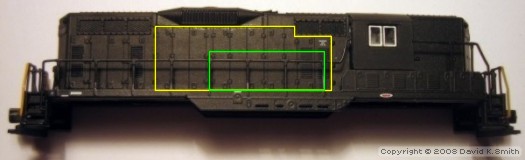

The secret to AZL's slender body is a combination of two factors: first, the chassis is only 6.75mm wide; then, the shell has a thin brass insert so that it can fit tightly down over the 8mm motor. Compare this to the Micro-Trains approach: their chassis is 8.15mm wide, and a full-thickness plastic shell must fit over it. The result can clearly be seen in the photographs above.

|

|

|

|

|

|

|

|

|

|

|

|

|

The two manufacturers appear to be substantially faithful to the prototypes with respect to the size and placement of details such as doors and louvers, right down to the subtle spotting differences between the GP7 and GP9 (the latter model representing an early version, having four 36" fans instead of two 48"). However, M-T had to make numerous compromises given the excessive hood width. For instance, the number boards are oversized, and while the grab irons on the ends are about the right width, they appear oddly narrow and misplaced.

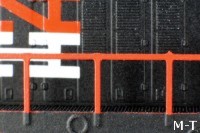

Where M-T really missed the mark, though, is with the fans: they're supposed to be "cap top" fans, which angle up towards the center to a dome. Although the fan on M-T's dynamic brake unit is slightly raised, the four smaller fans are dead flat—their exquisitely delicate grilles and impressive visible fan blades are thus a wasted effort. They're also missing the mounting flanges at the base of the housings, as well as the attachment bolts. And to my eye, the rounded corners of the hood appear to be too sharp. All of these gaffes have the unfortunate cumulative effect of accentuating the excessively wide hood, its top looking rather like a vast, barren plane. AZL nailed the fan shape—but with thick grilles and huge, HO-sized rivets and bolts! Also, the fan on AZL's dynamic brake unit is of an atypical style.

The undersides of the two models reveal more cosmetic differences. The ends of the air tanks on the M-T model are very shallow and expose a section of the metal frame, whereas the AZL air tanks run two-thirds of their full length for better visual effect. M-T went to more trouble than AZL to render the air lines, particularly on the fireman's side, although they look more like plates than pipes; AZL's simplified rendition, which is a valid alternative style, minimizes the plate effect. Finally, I'm not sure if it's because the shell rides high or the tank rides low, but there's an unsightly gap between the sill and the tank on the M-T unit.

The pilots of both models have no drop-steps or grab irons. The latter omission is less of an issue as there were several variations, from nothing to inverted Ls beside the steps to one long grab running the width of the pilot. M-T's pilot faces are completely devoid of any details which, together with the gaping hole, gives the model an unfortunate toy-like appearance; even the addition of MU cable stands would have helped. By contrast, AZL provides pilot inserts for body-mounted dummy couplers; the inserts feature pilot steps, cut levers and MU hoses—a huge plus for AZL in terms of appearance.

Micro-Trains used their GP35 mechanism exactly as-is for their GP9. This explains the truck spacing discrepancy: 32' for the model versus 31' for the real-life GP9. Being off by a foot over a 30+ foot span is not awful, by any means, and in this case it saved M-T quite a lot of new tooling costs, but using the same frame did force them to make the shell two and a half feet longer over the pilots than the prototype.

|

|

|

Introduced in 2005, M-T's mechanism is based substantially on the "industry standard" split-frame design now used by virtually every major model manufacturer in larger scales. An 8 mm Maxon coreless motor is fitted with a pair of tiny flywheels that couple to worms in bearing blocks over the gear towers. An opportunity for extra weight is traded for a nearly-plug-and-play DCC-ready design (one must remove and replace a pair of tiny springs that transfer current to the motor—you'll need tweezers, good eyes and steady hands to perform the upgrade).

Where M-T deviated from the current norm is the trucks: rather than outboard electrical pickup needlepoint bearings, M-T uses inboard axle bearings with wheel wipers for pickup. This was done in order to recycle several parts from their now-ancient F7 mechanisms—the plastic truck side-frame betrays its heritage with the clearance slot for the large worm gear of the F7. This is called saving money, and aside from locking them into a specific—if outdated—truck design, there's not much for which they can be faulted.

As much of a kludge as this may sound, it's not all that bad, since the design adaptation includes wheel wipers to transfer current directly from the backs of the wheels to the frame, circumnavigating the original convoluted path from the wheels through the bearings and up the split truck frames to the chassis. Inboard bearings plus wheel wipers equal a lot of extra friction, but given the tiny size of the parts, the amount of friction introduced is relatively minor—the model runs quite nicely in spite of all this.

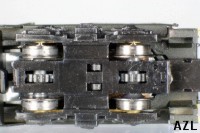

One cosmetic benefit of M-T's somewhat antiquated truck design is that it allows for narrower, more accurately-dimensioned trucks. Based on drawings, I've estimated the overall width of the prototype's Blomberg B truck at about 8 feet; M-T's measure 8'-3", whereas AZL's are over 10 feet. Unfortunately, placing correct-width trucks beneath an over-width body, which must fit over an 8.15mm wide chassis, just makes the body look that much wider!

|

|

|

The AZL "DCC-ready" mechanism is powered by an 8mm Faulhaber coreless motor fitted with the largest flywheels they could cram into the 6.75-mm wide chassis. The worms are integral parts of the flywheels, thus adding valuable mass and eliminating a dozen parts—along with the friction they'd add.

AZL followed the current industry-standard truck design with outboard electrical-pickup needlepoint bearings, which also make the trucks excessively wide (but better to have wide trucks, in my opinion, than a wide body—much less noticeable).

Rather than run the pickup wipers under the walkways, as is the norm these days, AZL elected to locate them under the frame right next to the gear tower, and the needle bearing contact parts jog inboard to meet them. Although I can only speculate as to the technical reasons they chose this approach, I can assert that it's cosmetically superior to the typical practice of placing the pickup wipers under the walkway, since it omits the visible portions of these parts. Evidently it was a challenge for AZL to get their design to work, as their pre-production units had some difficulties, but they appear to have ironed out the bugs for the production run.

By the way, AZL's mechanism has two traction tires, which do help with pulling power yet do not noticeably compromise electrical pickup in my test runs; they're located on the forward axle of the rear truck. The truck-mounted couplers are their own functional but non-automatic knuckle couplers; the pilot inserts have dummies. M-T's GP9 has no traction tires, and the truck-mounted couplers are naturally their own Magne-Matics.

Like most of its larger-scale counterparts, the M-T shell is comprised of three main injection-molded parts: hood, cab and walkway. Additional internal parts include light-shields that fit over the warm white LEDs, and light-conduits to pass the light to the headlight fixtures. Handrails are four etched brass parts bonded to the walkway. The only other add-on detail part is the horn.

AZL's engineers applied their thinking caps and designed a shell to fit over an 8 mm motor and still maintain a mean exterior width of only 8.6 mm. The shell has rectangular openings to clear the motor (green outline), and the openings are covered with etched brass inserts. These inserts follow the outline of the central cluster of access doors (yellow outline), and thus are nearly invisible. Micro-Trains has claimed they elected not to take this approach because they feared the brass inserts would separate from the plastic shell over time—and yet they glue on etched brass handrail parts! If they were so worried that the bond would fail, they could have easily added tabs to the brass insert that locked into holes in the shell. But this is all water under the bridge; Micro-Trains chose their path, and the results speak for themselves.

The AZL shell has a separately-applied dynamic brake blister, allowing them to offer two body styles without having to tool two whole hoods. Internal parts include a single light-pipe for the short hood, which is odd since it appears they could have just extended the LED the same way they had for the long hood. Shrink-wrap tubing on the yellow LEDs (deduct two points for not using warm white) provides light shielding.

Add-on detail parts include the horn and the hand brake on the nose. Handrails are four etched brass parts bonded to the shell; here, AZL designed a more robust attachment by folding the sill parts under the walkway, greatly increasing the surface area of the bond and adding rigidity to the parts. As mentioned previously, AZL also provides detailed pilot inserts with body-mounted dummy couplers. The truck-mounted couplers simply pop off by gently twisting the coupler pockets, and the optional pilot parts snap into the shell (with some effort).

|

|

|

|

|

|

|

|

|

Neither model has illuminated number boards. While some modelers aren't all that cranked about illuminated number boards (a few even un-illuminate them for improved appearance), I must admit M-T's are rather lifeless, an effect exacerbated by their excessive size; the number is just pad-printed right on the painted shell, with no effort to make the number board appear different from the body. AZL's number boards are separate inlays made of some sort of retro-reflective material that, under the right conditions, creates the illusion they're illuminated—a clever bonus... and a bit of a problem for anyone who needs to change the locomotive's number (like me).

Both models suffer for a lack of attachments at the ends of the side handrails. Both manufacturers designed the ends that meet the cab to simply sit in small recesses; and both manufacturers simply allow the pilot ends of the rails to hang free (where M-T didn't even bother to do anything with its shape—it just ends in mid-air, looking for all the world like a downspout). The result is that it's far too easy to accidentally bend the rails while handling the model, causing the free ends to twist out of position. Granted, it's relatively easy to carefully bend them back into place, but this really should not be a requirement of ownership.

Finally, both models are frustratingly difficult to disassemble, raising the already-high risk of handrail damage. M-T's is a bit easier once you know how they're held together: raised ridges, roughly centered over each truck, engage shallow slots in the shell just above the walkway. To remove the shell, first pull off the fuel tank; then insert four toothpicks, two on each side between the frame and the shell at each end of the fuel tank, and while gripping the chassis and the dynamic brake blister, slide the shell off.

AZL uses the more common bump-and-dimple system, which makes for more challenging disassembly because the dimples are located quite close to the chassis ends, where the shell flexes less. To remove the shell, insert four toothpicks, two on each side between the frame and the shell at each end of the fuel tank, and while gripping the fuel tank (it does not come off) and brake blister, pry the shell off using a gentle front-to-back rocking motion. Do not pull on the trucks, as they are easily ripped out of the chassis.

|

|

|

|

|

|

|

|

|

|

|

The tooling is much crisper, cleaner and more precise on the Micro-Trains model; rivets are so fine that magnification is required to see some of them. The AZL model suffers for its courser features, such as thicker grilles, grossly oversized rivets and so forth; the horns are outright chunky, as compared to the remarkably delicate M-T horns.

The tables are turned, however, when it comes to the etched metal sills and handrails. M-T's are good and sharp, but a tad crude—the handrails almost look like stamped tinplate, and the parts are sloppily cut from the frets. AZL's metal etching is generally more nuanced; the handrails in particular are finer, with three-dimensional details where the stanchions join the railing. One minor quibble, however, on the AZL: the louvered doors below the cab are rendered in reverse, with the joints between the panels raised instead of inset—done, I imagine, so as to render the latches and louvers properly, as compared to M-T's reversed (inset) latches and louvers. Only so much one can do in two layers, and on this small point I think M-T chose the lesser of two evils.

Micro-Trains wins hands-down for the precision of the injection molded parts: they fit snugly together, whereas AZL's have some visible gaps. M-T tooled the dynamic brake blister right into the shell; they do not offer a GP9 without dynamic brakes—which may result in some foobies for certain road names! Regardless, the shell is clean and seamless. AZL made a separate dynamic brake part, and offers their GP7 with or without dynamic brakes; the downside to this great option is that the add-on part slightly compromises appearance under close scrutiny.

Micro-Trains' painting is superior; they apply paint with a deft touch that leaves their fine tooling clearly visible. AZL's paint is thicker, giving the model's edges and details a kind of soft, melted-ice-cream look (their tooling may in fact be sharper than it appears, but I'm not about to strip a unit just to find out); I can attest, however, that there's no problem with paint adhering to their composite shell. The pad printing on both models is equally razor-sharp and clear; here, AZL gets extra points for including some of the warning labels and even the nearly-microscopic "F" on the head end of the sill.

Caveat: all observations with respect to appearance are road name-dependent, and points may be added to or deducted from either manufacturer's score for any number of reasons. As an example, M-T's generally high marks for painting gets dinged slightly by their New Haven scheme: they painted all of the etched brass handrail parts orange, then pad-printed black on the sill; this left a visible orange edge around the entire model. But then, AZL inexplicably left the horn unattached on GP7s without dynamic brakes, instead packing the horn in a little baggie with a cryptic diagram showing the installation location—yet there's no hole in the shell in which to mount it! Are we to make one, or surface-mount it? This is a real head-scratcher.

In general, both models are very smooth, quiet runners; the differences between them are relatively minor in the grand scheme of things. Here are the principal performance specifications (all electrical parameters measured using a filtered DC source):

|

*The difference in drawbar pull for the AZL is a consequence of whether the traction tires are on the truck's leading or trailing axle relative to the direction of travel. When the traction tires are on the trailing axle, traction is higher (and so too is the current draw at full slip). Since this is, oddly, when the locomotive is running in reverse, modelers looking for maximum forward-direction pulling power might want to swap the trucks.

AZL likely added traction tires to compensate for the locomotive's extreme light weight—less than one ounce. It certainly worked: its drawbar pull is nearly double or more than that of the ironically heavier M-T. At some point I intend to measure the AZL's pulling power without traction tires (which, for my purposes, are unnecessary).

The minimum sustained speeds may not be all that impressive, but these tests were done using a filtered and regulated DC supply, and performance should be improved by using a pulse-type throttle, or by switching to DCC. AZL's superior drive train is evident by the GP7's tendency to coast a little after power is cut, while the GP9 literally stops dead.

Both models track well, having no trouble negotiating some tricky trackwork that features handlaid Code 25 track, including a turnout, plus two pairs of transitions to Märklin sectional. Both models also easily negotiate the smallest-radius curved track made, which is Märklin's 5-3/4" radius sectional track (the minimum operating radius for the prototype scales down to 8", by the way). Impressively, AZL's body-mounted dummy couplers swing enough to prevent flipping cars on such curves. I have not attempted to install a Micro-Trains magnetic coupler in the AZL pilot (and I'm not inclined to do so).

List price for AZL's GP7 is $208.60, with typical retail of $189.00, and is rarely discounted any further. Depending on road name, list for M-T's GP9 ranges from $175.95 to $195.95; average retail is around $135.00 to $150.95, although I've seen them discounted as low as $112.50.

|

|

|

|

|

|

|

|

|

Both models are good-looking, fine runners, and any modeler should be pleased to own either one of them. In view of the market size, I believe they both represent good values. Ultimately I don't think there is one clear winner, as they each have distinct pros and cons, not the least of which are their marked dimensional and cosmetic differences; given that the corresponding real locomotives are essentially identical, double-heading the two models would create an awkward-looking lash-up!

While Micro-Trains' GP9 generally wins when subjected to macro-photography (barring those badly botched fans), AZL clearly went the extra mile to get their GP7's proportions right, and the result is a more convincing, true-to-the-prototype look—albeit only under the "two-foot rule" given the coarseness of its details.

The AZL also edges out courtesy of the pilot inserts; the M-T model, with those gaping holes in the pilots, bears an unfortunate resemblance to the earliest N scale diesels (an issue M-T will be correcting with their next release, an SD40-2). A retrofit pilot kit for the GP9 would go a long way to improve things, but it would not be a simple snap-together affair, since the old F7 truck frames need to be physically chopped.

Deciding between the two may involve some or all of the following criteria, which represent the primary distinctions between the models:

- the desired locomotive (GP7 vs. GP9)

- the desired road name

- better overall proportions versus finer detail and finish work

- whether or not automatic coupling is required

- pulling power

- price

IN MY OPINION

For myself, I went with the AZL GP7 entirely because of its better overall appearance, and now own three: two PRRs converted to Reading, and a C&O soon to become CNJ. I purchased the M-T New Haven GP9 for the sake of doing this review, and now that it's done I'll be selling the shell and using the chassis to power a heavily-modified F7. (I was hoping I wouldn't have to chop the chassis; I felt that the GP9 truck spacing of 31' was close enough to the F7's 30', but the actual spacing on the model is 32', and a two-foot difference is just too much to accept.)

All the same, I'll confess to having some gripes about the AZL. For one, I don't care for traction tires, and would prefer a loss in pulling power over a loss in electrical pickup reliability, even if it's marginal; traction tires also present problems as they age. And I find the coarser details, particularly those monster rivets, to be serious eyesores. Yellow LED headlights make for another minor ding in what could have been a truly exceptional model.

For what it's worth, I think it's a real shame that Micro-Trains chose to make "fat" locomotives out of a misguided notion that a composite shell would not hold together. Had they taken the same approach as AZL, they could have produced a real gem that would be the envy of larger scales, and I'd have taken out a second mortgage to buy a gaggle of 'em.

|

FOLLOW-UP

I've been accused of colluding with AZL and/or Ztrack Magazine to make Micro-Trains' loco "look bad" (seriously!). Nothing could be further from the truth! This is an honest review documented and written entirely by myself, with no outside influence whatsoever. Micro-Trains is simply infuriated that they didn't get 100% full marks for their less-than-stellar product. Sorry, Micro-Trains! You're just sore losers. Deal.

Copyright © 2007-2013 by David K. Smith. All Rights Reserved.