Roadbed

Once again I applied some valuable lessons from previous experience. Last time I used half-inch foamcore for both risers and subroadbed. However, this time I had some much trickier clearance issues to deal with, so I switched to 1/8-inch thick sheet styrene for the roadbed; I'd used this material previously for handlaid track and it worked well.

Rather than spend a small fortune on sheet styrene from one of the usual suppliers (such as Plastruct or Evergreen) and have to splice many pieces together, I found a plastics vendor online that sold large sheets at very reasonable prices.

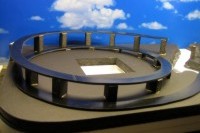

The arrangement of the helixes prevented cutting the roadbed from a single piece, so the plan was split into four parts. To get the dimensions right, I rendered the track plan in a computer drawing program and printed it out at full size. The cut lines were transferred to the black styrene using a sharp knife.

All of the cutting was done with a saber saw at its slowest speed to avoid melting. After sanding the edges clean, I clamped the two pairs of helix parts together with C-clamps and permanently joined them together using small styrene splicing plates bonded with liquid cement.

As with the previous layout, I cut risers from half-inch foamcore and glued them to the layout with carpenters glue. To bond the styrene roadbed to the risers, I used double-sided foam tape. The aggressive adhesive in this tape was more than adequate for the job.

The flat portions of the roadbed were bonded to the layout base with thick CA. I made this unusual choice based on a considerable amount of prior success in bonding cardstock materials to styrene. Thus all of the roadbed was literally installed in seconds.

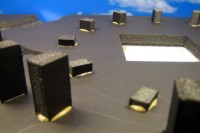

The roadbed outlines are transferred to the plastic with a sharp knife.

A saber saw set at its slowest speed is used to cut out the roadbed shapes.

Risers are made from pieces of half-inch thick foamcore.

The foamcore risers are glued to the base with carpenters glue.

The roadbed is installed on the risers and glued to the base with CA.

Copyright © 2007-2013 by David K. Smith. All Rights Reserved.