3. A New Way To Lay Track

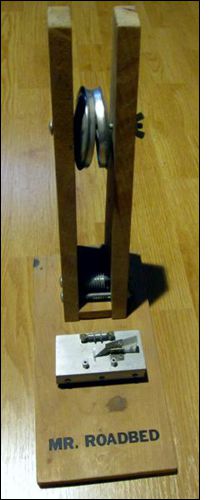

Several unique

construction techniques were employed, such as a totally new method of tracklaying: a custom tool (Mr. Roadbed, left) was used to

split double-sided adhesive foam tape lengthwise into slope-edged strips that resembled traditional cork roadbed. The foam tape

was simply applied to the subroadbed, and the track was then applied to the tape. (The technique is detailed in the March 1992 issue

of Model Railroader.) It's an astonishingly fast method that offers a number of unique benefits, and I still use the

technique to this day.

Several unique

construction techniques were employed, such as a totally new method of tracklaying: a custom tool (Mr. Roadbed, left) was used to

split double-sided adhesive foam tape lengthwise into slope-edged strips that resembled traditional cork roadbed. The foam tape

was simply applied to the subroadbed, and the track was then applied to the tape. (The technique is detailed in the March 1992 issue

of Model Railroader.) It's an astonishingly fast method that offers a number of unique benefits, and I still use the

technique to this day.

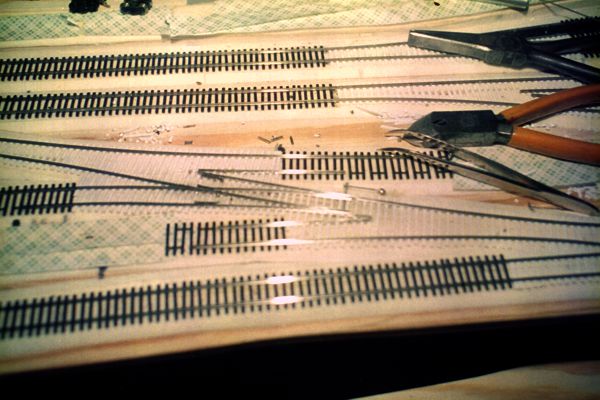

Another departure from traditional tracklaying was doing away with rail joiners. The rails and ties at the ends of each length of flex track are staggered; the longer free rails slip into the spaces left by the clipped-back rails. This helps eliminate misaligned track sections, especially on curves. Each section of track has its own set of redundant power feeder wires.

Probably the most unorthodox technique I employed was handlaying turnouts on styrene ties. I bonded the rails in place by heating them with a soldering iron; light pressure caused the rails to melt partway into the styrene. It sounds rather bizarre, but it actually worked quite well (see the first image below).

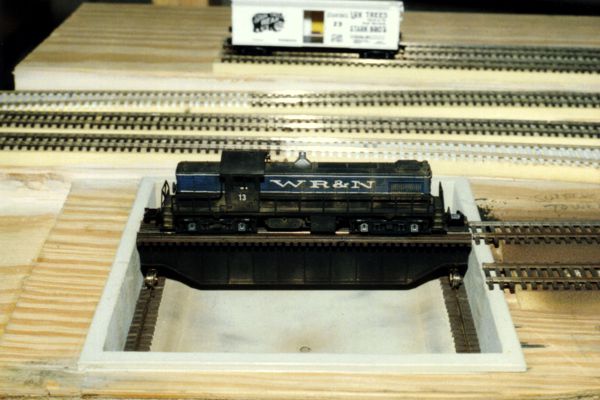

Still in its infancy, the WR&N was part of an open-house tour for the Mideast Division of the NMRA, during which dozens of visitors paid my nascent layout a visit. Although no trains were running, visitors seemed content to study the benchwork.

Handlaying turnouts on styrene ties.

Engine facility with turntable; mirror in the background.