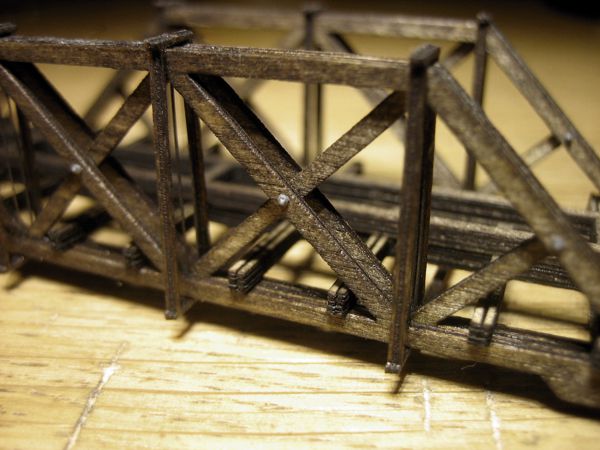

2.3. Truss Bridge

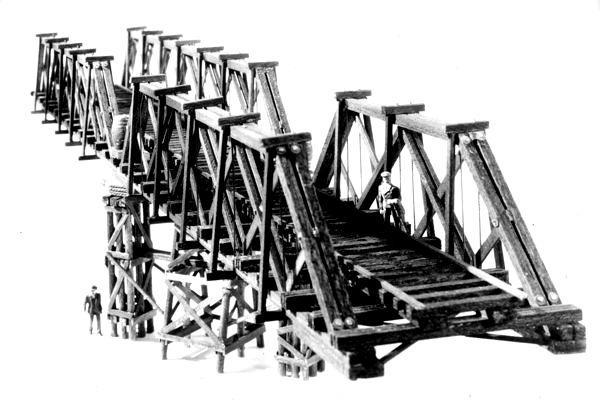

I considered a number of substitutes, including a single-span brass truss bride kit and N Scale plastic truss parts; I'd even modified and assembled the plastic trusses.

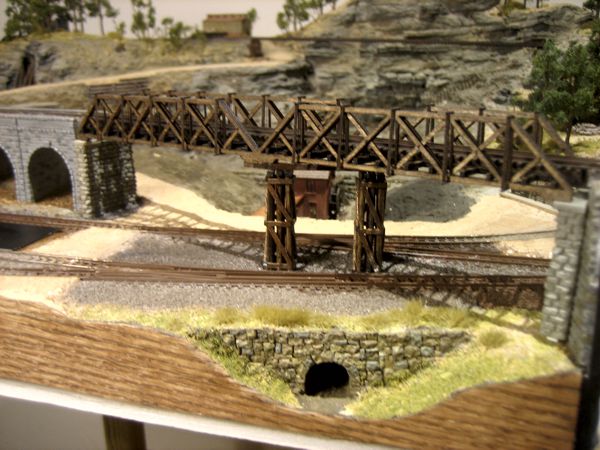

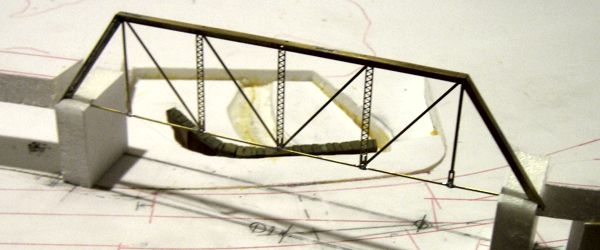

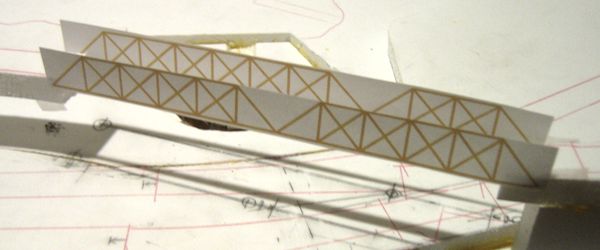

Ultimately I concluded there was only one way to do John Allen's truss bridge: the right way, just as it had been for the stone a rch bridge. It meant learning how to render laser-cutting drawings, but I was more than willing, and I've since mastered the skill profitably. Before doing any drawing, I made some paper templates to be sure I had the dimensions exactly right.

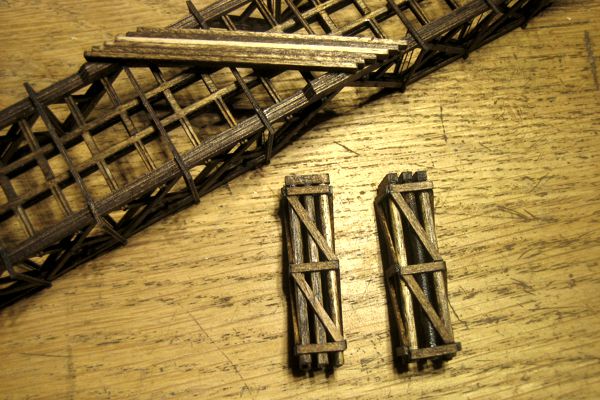

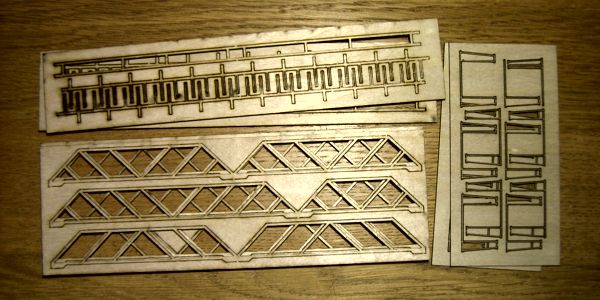

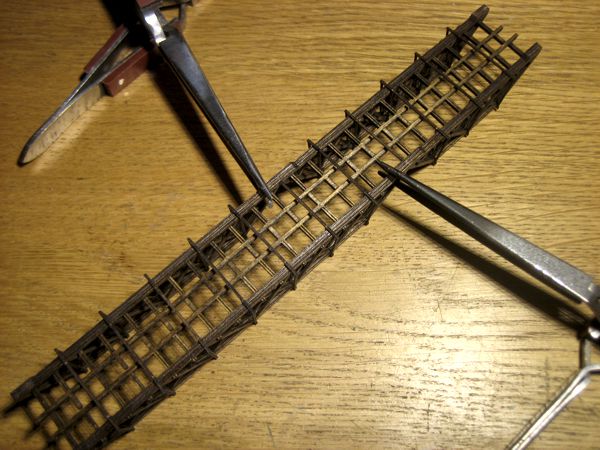

I designed the bridge with as few components as possible by merging assemblies together into groups, as well as making the bridge perfectly symmetrical, save for the offset on one side. (I didn't realize at the time that this was standard operating procedure for the industry; I thought I was being clever.)

The fellow who did the laser cutting for me insisted on "improving" my artwork. I had to insist—strongly—that he cut it exactly as I'd drawn it; otherwise, I wouldn't learn from my mistakes. As it happens, to my utter amazement, it all worked perfectly on the first try.

The center of the span was supported by a pair of scratchbuilt pilings (there wasn't quite enough room for the third support on the original).