Road Compactor

First Generation

Regrettably I don't have anything to show for this animation other than one blurry photo of the model. It's a GHQ road compactor modified so that the rollers would turn.

The left end of the model had a bit of brass tubing attached vertically; the tubing dropped over a pin protruding from the pavement. This pin moved back and forth through a slot in the pavement via a very simple crank mechanism under the layout. You can barely make out part of the slot in the photo above, just behind the compactor. The scene was arranged so the slot was hidden behind the building at the left; the compactor would then peek out from behind the building with each of its slow cycles. It was an example of how an animation can be effective when it can't clearly be seen.

Second Generation

By contrast, my second go at this was substantially different. It started when I found the old model; it was badly damaged but salvageable. As I was making repairs, I noticed a small bit of double-stick foam tape inside the recess in the main body. I vaguely recall attempting to use magnets to move it, and gave up—magnets are seriously challenging to make work effectively. The main problem is that the object being moved, even if it rolls smoothly, will move in a herky-jerky fashion.

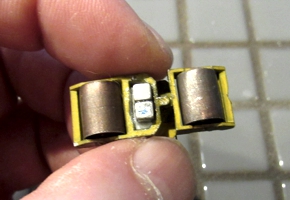

But magnets have come a long way, and so has my understanding of how to use them effectively, and after a few quick experiments, I learned that I could pull this off. There are some tricks to make this work: first, use the strongest magnets possible that fit the available space; and second, keep the magnets as close together as possible. To the first point, there are some seriously strong little magnets available these days. And to the second, I mounted the magnets on the compactor so that they almost touch the pavement (below left); I'm also using 0.010" thick black sheet styrene as the pavement.

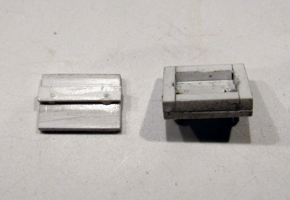

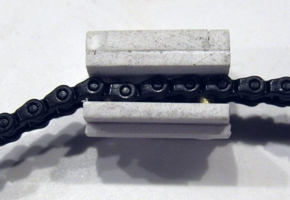

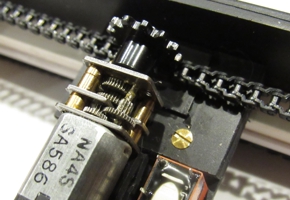

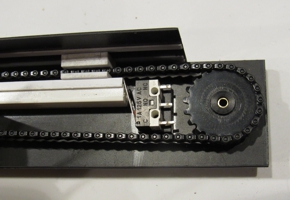

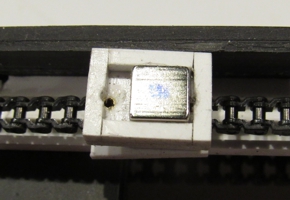

The next item on the agenda is how to animate it. The original was moved by a pin mounted on a rod connected to a crank. It's a very simple and effective device, but I wanted the compactor to move much further than its original travel of about an inch. Indeed, I wanted it to go about 5 inches, which would have required an enormous crank—not to mention an enormous visible slot! The solution was a miniature nylon chain drive system, assembled from a bunch of disused parts that had been sitting in a drawer for years (above right). This, combined with a reversing circuit, would be perfect.

The drive magnet rides in a sled connected to the chain with pins (above and below).

The sled slides in a track on the main frame, while the magnet (which is not glued or or otherwise attached to the sled) rides in track on the underside of the pavement (below left). A low-RPM motor drives the chain (below right)

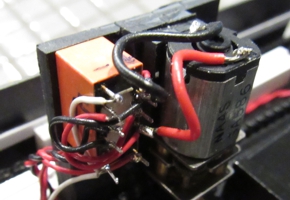

Limit switches reverse the direction (below left) by energizing a DPDT latching relay (below right).

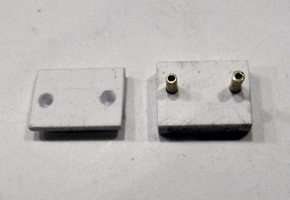

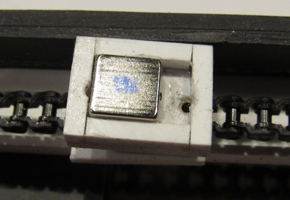

One last detail: the drive would reverse instantly, whereas the compactor ought to pause briefly before reversing. Doing this electronically would not have been trivial; the much simpler solution was to do it mechanically. The driving magnet sits in a sled with a slot that provides a little forward-backward play (below, left and right); when the drive is reversed, it takes a moment for the magnet to catch up with the sled.

The circuit is relatively simple, although it does require two different voltages to control motor speed; this is handled by a DC-DC adjustable voltage regulator for the motor.

|

|