Gas Station Car Lift

This page rolls together both indoor and outdoor car lifts, since conceptually and operationally they're the same. Perhaps not surprisingly, I was inspired by the one Rick Spano made for his Sceniced and Undecided:

|

|

First Generation

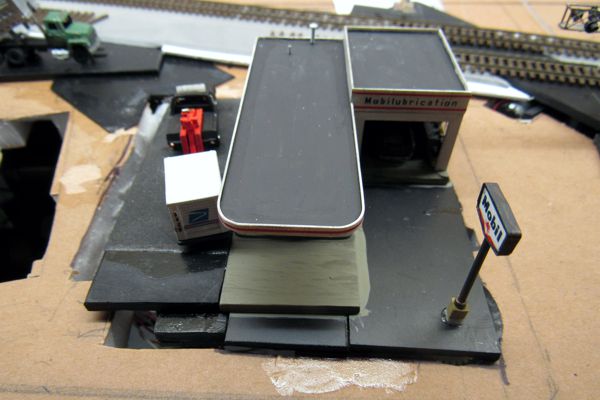

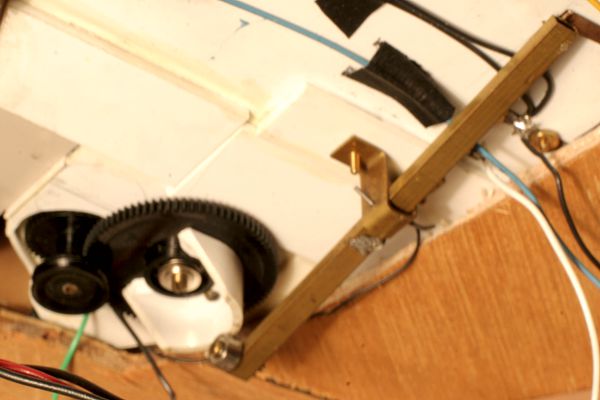

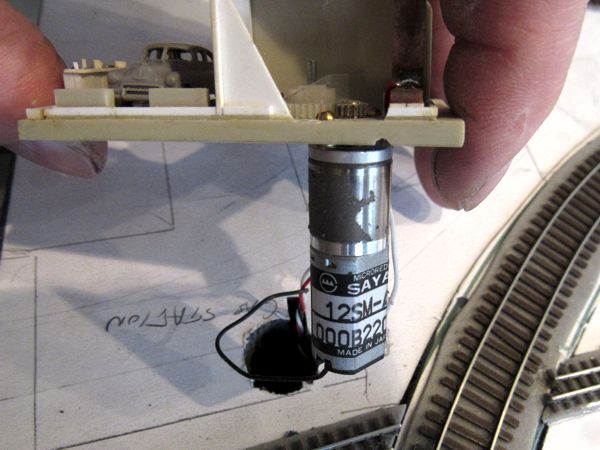

In the late 1990s, I built my first car lift, which went inside a gas station on my White River & Northern IV, above (photo by Lou Sassi). As seen below, the mechanism is a simple cam with a long follower that acts like a see-saw. Incidentally, the same motor drives a lighted rotating sign through a long belt, omitted here for clarity.

I never shot a video of it on my layout, but had the chance after I donated it to Rick.

|

|

Second Generation

I enjoyed making the gas station for the WR&N IV so much that I did it all over again in 2014, long before I'd started any layout project were it might be used. My plan was to make a diorama that would subsequently be incorporated into a permanent layout, which is more or less how it played out.

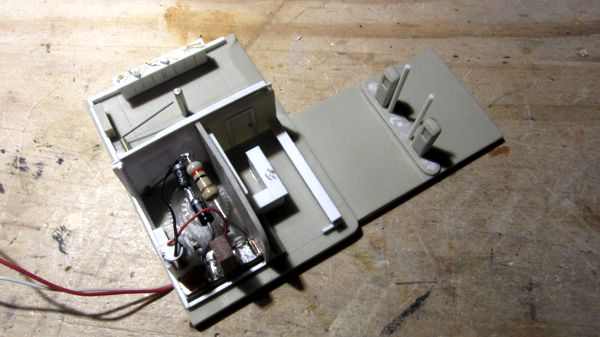

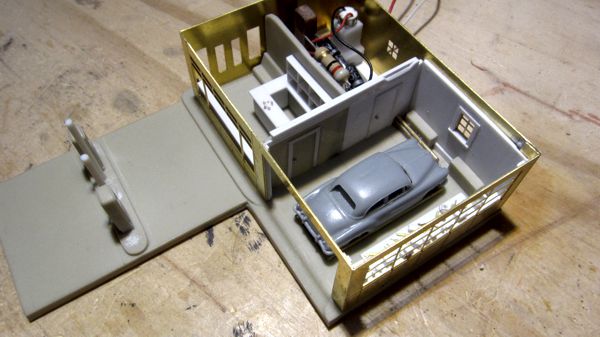

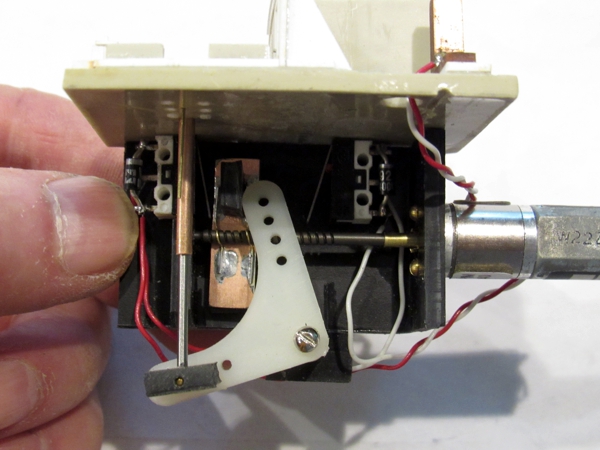

By the time I got around to taking photos, I'd already finished the base and built the car lift mechanism. Unlike the original, where all of the works were under the layout, this one is entirely self-contained: a pager motor with a double-worm reduction slowly turns a cam that lifts the car with a Z-shaped rod. Everything is hidden in the restroom.

The diodes and resistor provide the motor with constant 1.5 volts, regardless of what the supply voltage is. The square copper-colored post to the right of the motor provides power for lighting via contacts mounted on the roof.

The car lift itself is a brass assembly; the hydraulic pole is actually stationary, and fits inside the car when it's lowered. Thus, nothing sticks out the bottom of the structure. I would love to have animated the roll-up door as well, but that was a bit too much to cram into the space.

The interior is fully detailed—or will be when it's done; I still need to make some more tool boxes, a fan belt rack, a cash resister, and products for the shelves in the office, amongst other things.

|

|

Eventually this was installed on the Mountain Vista Railroad. Owing to the failure of the pager motor, I had to re-motor it.

Third Generation

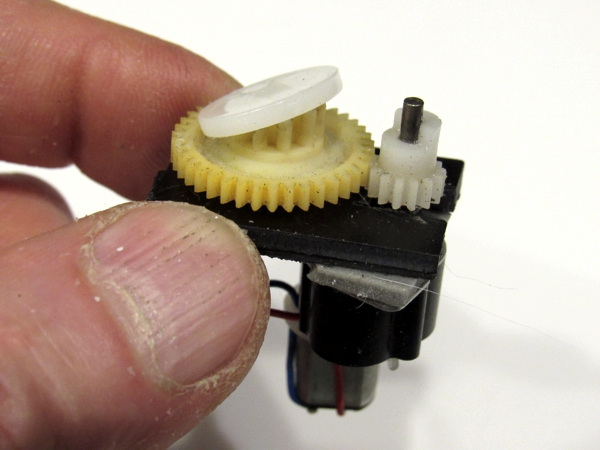

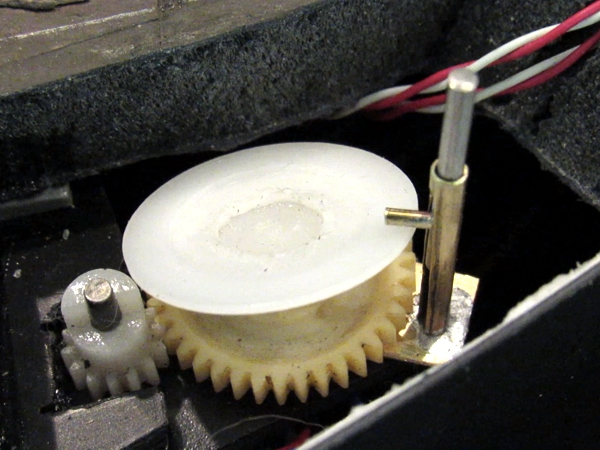

After the Mountain Vista was decommissioned, the gas station went into limbo. But I started a new project, an outdoor lift for the White River & Northern X. The challenge for this one was to design the lift such that it didn't impinge on the tunnel space underneath the station, and I had barely enough room to do that. I also had to accept the fact that the mechanism would be inaccessible once the scene above it was completed, thus it needed to be very robust. I started with the lowest-RPM geared motor I had, which thankfully was also fairly quiet. The motor would drive a single gear having a cam attached. To simplify the cam, I simply mounted a nylon disc on the gear at an angle, as seen below. (Technical aside: This particular style of cam produces a sinusoidal motion, the same as a crank drive. Although this is less realistic, the movement is so slow that it's a non-issue.)

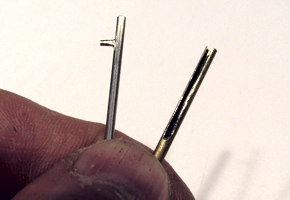

The "hydraulic" part of the mechanism is a steel rod that fits in a brass tube. I cut a slot in the tube to index the rod, and soldered a brass pin to the rod that would slide through the index slot (below left). When assembled, I had a "piston" for the lift table (below right).

Then I soldered the assembled "piston" to a small brass plate, and mounted it on the motor drive (below). The pin rides the edge of the motorized nylon disc, which I had to enlarge in order to get the amount of travel I needed.

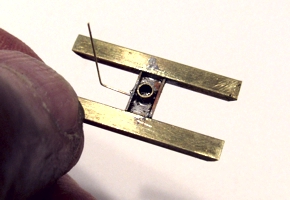

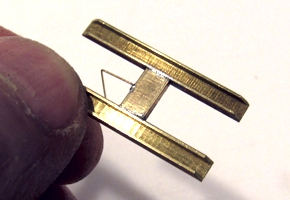

I made the lift itself out of brass channel stock (below left); a thin brass wire keeps the lift from spinning around (below right). Since gravity lowers the lift, it works more smoothly with more weight, so there will be a cast pewter car on the lift. The assembly simply drops onto the end of the steel rod.

|

|

Fourth Generation

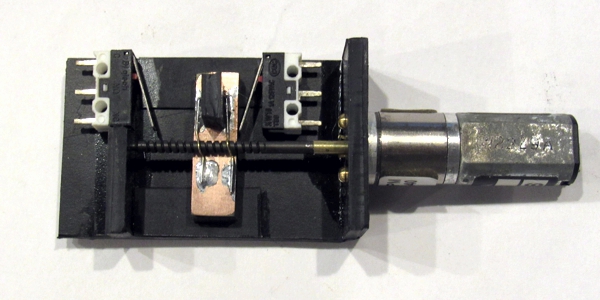

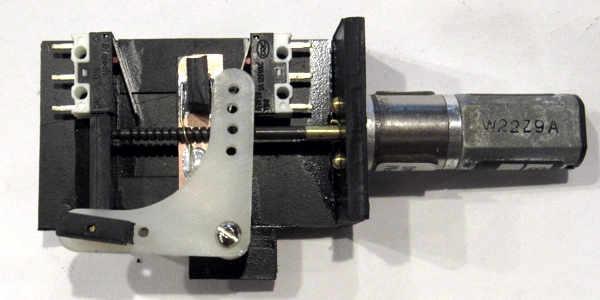

With the White River & Northern X decommissioned, and the new Men at Work diorama under way, I needed yet another new car lift mechanism, this time to replace the second generation version. That one had multiple issues, the most significant being the motor failed, the mechanism needed to be more robust, and the lift needed an alignment rod to keep it from "wandering." This time I decided to go linear; I had some old CD players in the junk box, so I scavenged a threaded rod from one of the drives. A geared motor, couple of microswitches and some odds and ends yielded a nice little linear mechanism.

Because such drives tend to be long, I added a bell crank to the mix so the drive could be mounted horizontally; otherwise, the mechanism was nearly twice as deep as that for the excavator.

The car lift itself is not physically connected to anything; gravity holds it down against the lifter on the bell crank. Incidentally, the lift itself is from the third gen outdoor lift, and not the "upside down" second gen one. Also, I had to mill out an opening in the ceiling to provide the new vehicle (a pickup truck, which is taller than the sedan it replaced) with enough room to rise all of the way up.

The control circuit is relatively simple. The DPDT panel switch provides manual control of the lift, with the switch showing the lift's position.

|

|

Final revision: in order to make room for the oscillating desk fan in the station office, I removed the lift drive mechanism, removed the bell crank, turned the mechanism 90 degrees, and reinstalled it. The lift "piston" is now raised by the part that used to engage the bell crank. 30 July 2022 it all came together.