Electrical

Service

As I'd related in my battle for electricity, getting service to the house was not a trivial process. Indeed, it took years and was made many times worse than it was at the outset owing to new requirements established in January 2018 by JCP&L. Service was at long last connected and the house energized 29 October 2018.

Fixtures

Some of what I did wasn't by choice due to code requirements. Specifically, I've got three or four times as many outlets as I really need, because they're mandated by code. In any living space, there must be an outlet no further than six feet from any point along a wall (i.e., every 12 feet). That meant having to embed outlets in the columns on the windowed wall in the living room, which was not a trivial process—unsightly outlets only to make some inspector happy:

Also, there must be a 20-amp GFIC outlet no further than two feet from any point along a kitchen countertop (i.e., every 4 feet). Thus I also have a surfeit of outlets in the kitchen that I'll never use: at most I might need one, maybe two, but code dictates I must have seven, five of which are seen below. Plus, there must be at least one outlet on an island.

Like the main living space, my office and studio are likewise bristling with outlets that I not only don't need, but will eventually cover up with built-in cabinetry. On the other hand, the outlet requirement for a garage is pretty minimal—only one is necessary—whereas my garage includes a workshop, so I've installed eight. Half of them can be seen below, along with boxes for six 4-foot overhead light fixtures.

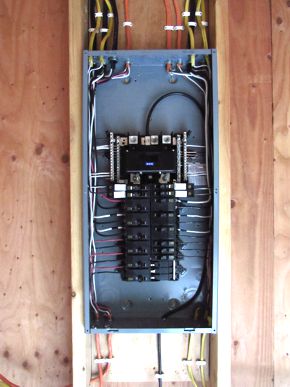

Breaker Panels

The garage is home to the main breaker panel (#1 on diagram at right; photo below left), next to the garage door and directly adjacent to the meter outside (#2); it handles all of the utilities, such as the HVAC system, water heaters, appliances, etc. Located conveniently next to the inside garage door, a sub-panel (#3; below right) has all of the general lighting and outlet breakers. This actually simplified the wiring by pulling a half-dozen circuits out of the main panel, and it saved over 200 feet of wire at the same time.

By the way, all of the sub-panel breakers had to be special new "arc fault" types, which are three times the price of ordinary breakers. This is the consequence of manufacturers looking for ways to boost profits: they participate in establishing the electrical codes we must follow, so they get to force us to use new products, regardless of whether or not they're truly necessary or effective. For instance, I must also have "tamper-resistant" outlets everywhere, even though there will never be any (human) children living here. That's just the way the system works.

Some code requirements can leave you scratching your head. For instance, the breaker box labels cannot be written by hand, no matter how neat and legible your writing may be! Instead, they must be printed by some means, such as a labeling machine or computer-generated artwork. Go figure.

Rough electrical inspection took place on 9 November 2018. It was done so quickly that I never even had a chance to get anxious about it. As it happened, I could have had thousands of violations and they'd never have been caught. But, just to be clear, I went above and beyond to ensure everything was up to code, right down to the wire staple spacing.